Industrial News

-

42 Inch Gate Valve Repaired successfully!

FLUIDCHEM recently repaired a 42” (2nos) Gate Valve for a Steel Plant in central India in less than 9 days. The client required a solution to repair its 42” (DN 1050) Gate Valves, which other valve repairing companies were unable to do so because of its size. We carried out body and wedge seat lapping using our Portable Valve Grinding and Lapping Machine. We ensured that our customers gate valve remained operational, reliable and efficient for at least another one year, which is essential to their ongoing operation.

THINK BIG! DN 1200 Gate Valves for a Steel Plant in India.

The production and supply of six valves DN 1200 was recently completely from our factory in Ahmedabad. Weighing at 5.5 tons and standing a majestic 16 feet tall, FLUIDCHEM’s Rising Stem Gate Valve was designed and manufactured for a steel plant in India where nearly all manual valves installed are from FLUIDCHEM. These 48 Inch Gate Valves were designed, manufactured and tested successfully within 18 weeks, much before the customers deadline.

FLOATING BALL VALVES from FLUIDCHEM! Provide superior leakage resistance, shorter lead times, reduced costs.

FLUIDCHEM, a leading provider of flow control products and services for the global industrial markets recently increased their product range of Floating Ball Valves. We now have a complete range of Floating Ball Valves like Single Piece Design, 2 Piece Design and 3 Piece Design Ball Valves.

These quarter-turn, floating ball valves have been reengineered for global availability by standardizing design, materials, construction and product certifications. Target applications for the valves include controlling the flow of liquids or gases in the following industries: chemical processing, petrochemicals, energy, defence, food and beverage, industrial gases, pharmaceuticals, and water.

For more information on these valves, please contact our sales team today!

FLUIDCHEM invests in new range of valves

FLUIDCHEM has invested in a new range of valves, specifically aimed at the Chemical, Pharmaceutical and Sugar industry. This investment is part of a growth initiative that features within the company’s ongoing expansion plans.

FLUIDCHEM has also increased its production capacity for Ball Valves, Butterfly Valves, Gate Valves and Sluice Valves which are all manufactured in conformance with relevant industry standards. The size range of these valve varies from 1” to 36” and are available with either lever (handles), gear box or pneumatic actuators.

For more information on these valves, please contact our sales team today!

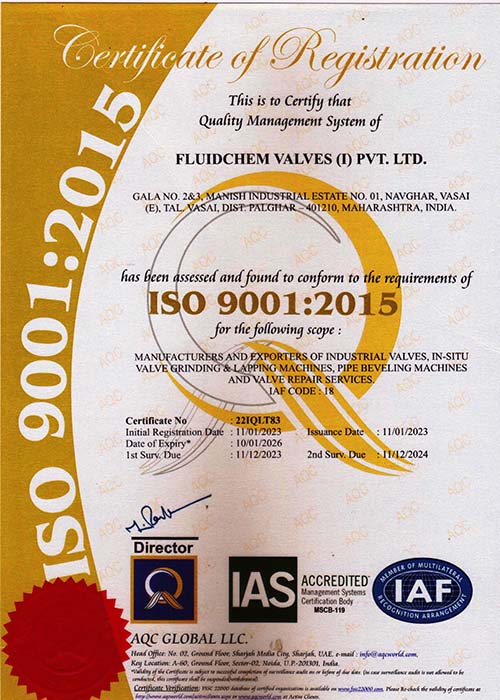

Renewal of ISO 9001 certification

Continuing with our commitment to provide customer excellence, FLUIDCHEM is proud to announce its renewal of ISO 9001:2015 certification.

FLUIDCHEM’s achievement demonstrates not only the presence of a clear quality management system that flows throughout the company but is also a sign of commitment to our clients, collaborators and suppliers that we provide the best in product, service and continuous quality improvement.

ISO 9001 is the world’s most recognized quality management standard. Developed by the International Organization for Standardization (ISO), it helps organizations meet the expectations and needs of their customers.

Needle Valves: 13400 manufactured in 2022

During the past year we have manufactured and supplied around 13400 units of Needle Valves, in sizes up to 2″ (50mm), made in a wide range of special materials and meeting diverse requirements. These valves were for various different applications and industries. Our Needle Valves are available in a wide range of port, orifice sizes and pressure ratings.

For more information on needle valves, please contact our sales team today!

Pipe Bevelling Services From Fluidchem!

Pipes are crucial applications for all major industries like power, petrochemicals, oil & gas, fertilizer and others. As pipe leakage and downtime lead to significant loses, FLUIDCHEM aims to reduce your downtime and avoid your pipe leakages problem.

While our Valve Maintenance services ensure “No Leakages” for your valves, our pipe bevelling maintenance services prepares your pipes for faster maintenance. FLUIDCHEM’s pipe bevelling machines ensures an easy fit on existing piping systems and bevel pipes with greater accuracy leading to minimum material wastage. The result being, safe preparation of pipe ends for welding to ensure consistency and quality including straight cut, bevels, compound bevels, J-bevels, compound J bevels and all custom weld preps.

Our Pipe Bevelling Machines are also far more faster and accurate than hand grinders and other conventional methods of bevelling and produces a near perfect quality bevel every single time. We have the machines to bevel pipes from 12mm to 600mm of any type of metal with a wall thickness of 20mm and less. Bevelling Tools of different angels are also available to meet your requirement.

When you need fast, accurate precision machines bevels, call FLUIDCHEM!

Another Day, Another Valve, Another Brand, Another Project, Another Challenge, Another Satisfied Customer!

Team FLUIDCHEM successfully repairs a 20” x 300# Severn Glocon make Control Valve for a Petrochemical Plant in India recently.

Another Shutdown Completed!

FLUIDCHEM recently completed yet another well organized annual shutdown for a Refinery in North India. All scopes of work were completed without leakage, safely and within the given duration. Bravo Team FLUIDCHEM!

Connect To The World Of FLUIDCHEM!

Follow us on Facebook, Instagram, Linkedin and Youtube. You can find news and information about us on these social media platforms, where we will regularly post images, videos and information about our most recent activities and achievements.

Website Launched!

The valve industry is changing rapidly, modern commerce demands visibility and engagement through the digital world and FLUIDCHEM Valves (I) Pvt Ltd. are delighted to be engaging in this mode of connecting with our customers.

Our brand-new website is live! This marks the first phase of expansion for the digital side of our business. The website will be a medium used to share helpful information, product and service news, technical data sheets of products, announcements and latest company news, all created in-house by our marketing department.

As the industry is diversifying and becoming increasingly digital, we felt it was the right time to create a faster more user-friendly website, helping to prove to our customers we are at the forefront of innovation. Digital is an ever-increasing channel and we recognise the importance of participating and connecting with the greater world in a way our modern customers have come to expect.”

Our new interactive site is faster and better equipped to handle modern web surfing by being fully mobile integrated, allowing our customers to browse with ease and “on the go”. Visitors to the site will have easier access to our product ranges, like the Valve Lapping Machines, Industrial Valves, Pipe Beveling Machines and be able to explore the options of selecting various different types of consumables available with us.

We have also updated our ISO and CE certification, connected our social media profiles and our newest product brochure is now available to download. An in-depth section about our top management and recruitment is also available on our site now.

Some technical data and sections in the website will be updated from time to time. We invite our esteemed customers to visit our website on a regular basis and provide inputs as to what else you would like to see here. Feedback could be mailed to me directly at azhar@fluidchemhava.com