FG Series Valve Lapping Machine

Purpose

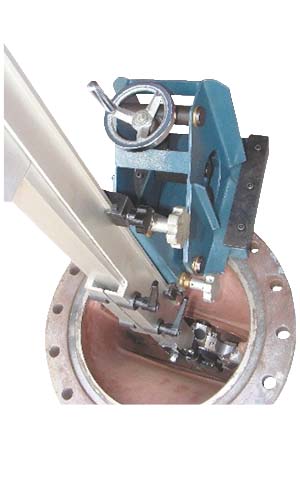

The FG Series Valve Grinding and Lapping Machines are designed for In-Situ grinding and lapping of Body Seat and Wedge Seat of Gate Valves, Parallel Slide Valves, Swing Check Valves as well as Flat Seated Globe Valves without dismantling the valves from the pipeline. These machines are also suitable for shop floor and repair bay applications.

Features

Portable, Yet Durable :

FLUIDCHEM’s FG Series Valve Grinding and Lapping Machine is a robust gear operated, but light weight grinding and lapping machine for in-situ or in-shop repair of damaged valve seats.

Design :

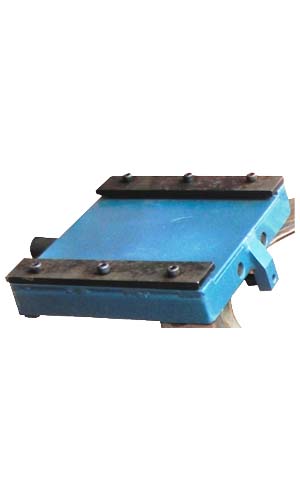

The FG Series Valve Grinding and Lapping machine is a gear driven lapping machine which results in a very high material removal rate with extremely good flatness accuracy. Also individually driven grinding heads gives an absolute flat sealing surface.

Drive Available:

All models are available with either Pneumatic or Electric Drive

Wet or Dry Lapping:

All models can be used with either Abrasive Paste (wet lapping) or Abrasive Paper (dry lapping) by simply changing the grinding discs.

Abrasive Papers:

Self-adhesive grinding discs of Grit 80, 120, 220, 400 are supplied by default with every unit.

Stellited Surface:

Grinding stellited surface with CBN discs is also possible with our machines.

Suitable for all pressure class :

Our machines are suitable from ASA 150# to ASA 4500# class of valves.

Sizes :

FLUIDCHEM’s In-Situ Gate Valve Grinding and Lapping Machines are available in standard dimensions from size 200mm to 1000mm (See Table for more detail). Non standard sizes are also available on request. We regularly manufacture custom make machines as per client’s requirement.

Packing :

All units are supplied complete with all accessories and consumables to cover the full range of the machine. Spares, instruction manual and warranty certificate are also supplied as standard along with each machine.

Parts Machines:

Sealing surface of Gate Valves (Body Seat & Wedge Seat).

Sealing surface of Globe Valves (Flat Seat)

Sealing surface of Swing Check Valves and Parallel Slide Valves

Advantages

It can be used for grinding and lapping of both flange-type and flangeless valves.

It can be used for grinding and lapping of both flange-type and flangeless valves.

Our machines are easy to assemble, set and install.

Our machines are easy to assemble, set and install.

These machines are flexible in operation and easy to maintain. They can be used vertically or horizontally at site and at workshops.

These machines are flexible in operation and easy to maintain. They can be used vertically or horizontally at site and at workshops.

The FG Series Valve Grinding and Lapping Machines can be used for horizontal and vertical seat valves (Gate Valves and Globe Valves)

The FG Series Valve Grinding and Lapping Machines can be used for horizontal and vertical seat valves (Gate Valves and Globe Valves)

High-grade surface finish is achieved by using either abrasive paper or abrasive paste.

High-grade surface finish is achieved by using either abrasive paper or abrasive paste.

The main purpose of these machines is to grind and lap body seat and wedge seat of Gate Valves, however they can also be used to remove flange raised face and do lapping on bonnet flange.

The main purpose of these machines is to grind and lap body seat and wedge seat of Gate Valves, however they can also be used to remove flange raised face and do lapping on bonnet flange.

All our valve grinding and lapping machines are CE certified and are available for sale worldwide.

All our valve grinding and lapping machines are CE certified and are available for sale worldwide.

Models Available:

- Working Range :

200mm to 300mm (8” to 12”)

- Submersible Depth (SD) :

Assembly 1 Submersible Depth : 900mm

Special up to : 1200mm

- Minimum distance between two valve body seat rings: :

77mm

- Drive :

Electric (230/120 V, 50/60 Hz)

Pneumatic (6-7 bar)

- Operation :

Grinding and Lapping

FG-300

- Working Range :

200mm to 600mm (8” to 24”)

- Submersible Depth (SD) :

Assembly 1 Submersible Depth : 900mm

Special up to : 1400mm

- Minimum distance between two valve body seat rings :

77mm

- Drive :

Electric (230/120 V, 50/60 Hz)

Pneumatic (6-7 bar)

- Operation :

Grinding and Lapping

FG-600

- Working Range :

200mm to 800mm (8” to 32”)

- Submersible Depth (SD) :

Assembly 1 Submersible Depth : 900mm

Assembly 2 Submersible Depth : 1400mm

- Minimum distance between two valve body seat rings :

77mm

- Drive :

Electric (230/120 V, 50/60 Hz)

Pneumatic (6-7 bar)

- Operation :

Grinding and Lapping

FG-800

- Working Range :

200mm to 1000mm (8” to 40”)

- Submersible Depth (SD) :

Assembly 1 Submersible Depth : 900mm

Assembly 2 Submersible Depth : 1400mm

- Minimum distance between two valve body seat rings :

77mm

- Drive :

Electric (230/120 V, 50/60 Hz)

Pneumatic (6-7 bar)

- Operation :

Grinding and Lapping