We set the standards others try to live up to.

Established in 1988, FLUIDCHEM is one of the leading manufacturer of Portable Valve Grinding and Lapping Machines in India with a proven reputation for excellence in product quality, reliability and the highest level of customer service. FLUIDCHEM pioneered the concept of In-Situ Valve Lapping in India with its unique products in late 80s and early 90s. Since then, we have grown from a small family-run business into a global brand, supplying products in over 5 continents.

We engineer and supply high-quality products to perform in some of the most severe service conditions throughout the world. As experienced valve and valve maintenance equipment manufacturers, we have built a reputation for providing high-performance products on time and at a competitive price.

In-Situ Valve Lapping Machines

FLUIDCHEM is one of the leading manufacturers of Portable Valve Grinding and Lapping Machines in India with a proven reputation for excellence in product quality, reliability and the highest level of customer service. We pioneered the concept of In-Situ Valve Lapping in India and have exported our products to over 35 countries in 5 different continents over the years.

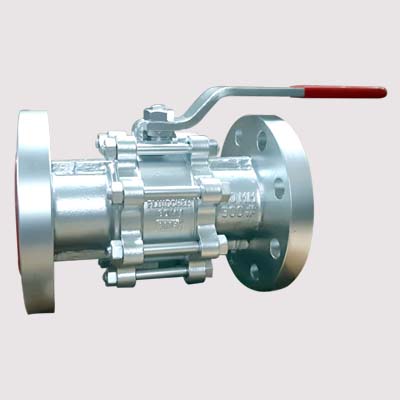

Industrial Valves

FLUIDCHEM is well known for having the most reliable and safest valves in the market, and is backed by over 20 years of experience, technology, innovation, know-how, references, operating time of the valves and a fully in- house manufacturing process. We have one of the widest ranges of valves in the market, offering highly engineered ball, gate, globe, check, butterfly, knife gate, sluice, and more.

Valve Repairing Services

Whether you need a globe, check, gate, safety or control valve to repair, FLUIDCHEM can handle complete valve repair services on ALL types of valves. We are one of the leading Industrial Valve Repairers with modern state-of-the-art equipment and machinery to repair any make, type, size and pressure class of Industrial Valves at site and at our factory.

00+

Domestic Customer

00+

Countries Exported

00+

Portable Machine Installation

00+

Product Line

Pipe Beveling Machines

FLUIDCHEM the beveling specialist! We manufacture ID and OD Mounted Pipe Beveling Machines suitable for small, medium and large pipes.

Frequently Asked Question

Question: How will FLUIDCHEM’s Portable Valve Grinding and Lapping Machine benefit my plant?

Answer:Removing a leaking valves and sending it to a workshop for repairing is an expensive and time consuming process. FLUIDCHEM’s In-Situ Valve Grinding and Lapping Machines allows your valves to be lapped in-situ, hence reducing downtime and costs incurred in material replacement, transportation, logistics and labour. In comparison with conventional manual lapping techniques, we are able to reduce the lapping time up to 90%. Our machines are designed and manufactured to provide maintenance engineers with a perfectly functioning equipment and companies with a profitable investment.

Know MoreQuestion: What are the different valve repairing services you offer?

Answer: We at FLUIDCHEM offer the following services:-

- Annual Rate Contracts for all types of Valves.

- Routine repair and maintenance of valves during outages / turnarounds.

- In-Situ Valves Repairing & Testing during Annual Turn Around.

- Shut down and emergency valves maintenance.

- Workshop repair and testing.

- In-Situ Lapping of high pressure valves using FLUIDCHEM make In-Situ Lapping Machines.

- Remanufacturing valve trim parts such as spindles, valve body seats, wedges/discs, and plug and seat rings.

Question: What is Pipe Beveling?

Answer: Pipe Beveling is a process where an angle is formed between the edge of the end of a pipe. When the pipe end is formed with a certain degree of an angle, it is called a beveled end. Pipe Beveling is an essential step in the welding preparation process of pipe joining.

Know MoreQuestion: What are the types of valves FLUIDCHEM manufacture?

Answer: We manufacture Gate Valves, Globe Valves, Check Valves, Ball Valves, Butterfly Valves, Knife Gate Valves, Forged Steel Valves, Wafer Check Valves and Strainers. For more details on each product and their application, please visit the Industrial Valve Page on this website or contact our office.

Know MoreQuestion: Is FLUIDCHEM privately owned?

Answer: Yes FLUIDCHEM is a privately owned Indian company that has been manufacturing and supplying valve maintenance equipment since 1988 and industrial valves since 2008

Know MoreIndustrial News

THINK BIG! DN 1200 Gate Valves for a Steel Plant in India.

The production and supply of six valves DN 1200 was recently completely from our factory in Ahmedabad. Weighing at 5.5 tons and standing a majestic 16 feet tall, FLUIDCHEM’s Rising Stem Gate Valve was designed and manufactured for a steel plant in India where nearly all manual valves installed are from FLUIDCHEM. These 48 Inch Gate Valves were designed, manufactured and tested successfully within 18 weeks, much before the customers deadline.

42 Inch Gate Valve Repaired successfully!

FLUIDCHEM recently repaired a 42” (2nos) Gate Valve for a Steel Plant in central India in less than 9 days. The client required a solution to repair its 42” (DN 1050) Gate Valves, which other valve repairing companies were unable to do so because of its size. We carried out body and wedge seat lapping using our Portable Valve Grinding and Lapping Machine. We ensured that our customers gate valve remained operational, reliable and efficient for at least another one year.

FLUIDCHEM invests in new range of valves

FLUIDCHEM has invested in a new range of valves, specifically aimed at the Chemical, Pharmaceutical and Sugar industry. This investment is part of a growth initiative that features within the company’s ongoing expansion plans. FLUIDCHEM has also increased its production capacity for Ball Valves, Butterfly Valves, Gate Valves and Sluice Valves which are all manufactured in conformance with relevant industry standards.